1390 Makina odulira olondola kwambiri

Zowonetsera Zamalonda

Technical parameter

| Malo ogwirira ntchito | 1300 * 900mm | Laser Head Brand | Ma Raytools |

| Mphamvu ya fiber laser | Zosankha: 1000W/1500w/2000w/3000W etc. | Core Components | Galimoto |

| Max kudula liwiro | 0-40m/mphindi | Mbali:

| Zotsekedwa kwathunthu |

| Bwerezani kulondola kwa malo | 0.02 mm | Njira Yogwirira Ntchito | funde mosalekeza |

| magetsi | 220v/50Hz/60Hz | mota ndi driver | Japan YASKAWA servo motor & driver/French reducer |

| Kutentha kwa chilengedwe | 0-35 ° C | Zojambulajambula Zothandizira | AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP |

| Nthawi yogwira ntchito mosalekeza | 24 maola | Malo Odulira | 1300*900mm, 1300*1300mm |

| Kulemera kwa makina | 1500kg | Mfundo Zogulitsa | Kulondola kwambiri |

| Natural moyo laser | 100000 maola | Njira yotumizira | Kutumiza kwa mpira wononga |

| Control Software | Cypcut | MAX mathamangitsidwe | 0.5G |

| Kuzizira System | Kuziziritsa madzi | Bwerezani kulondola kwamalo:

| ± 0.006mm |

Kudula makulidwe

| Laser Cutting parameter | ||||||||

|

| 500W | 1000W | 2000W | 3000W | 4000W | 6000W | 8000W | |

| Zakuthupi | Makulidwe | liwiro m/m | liwiro m/m | liwiro m/m | liwiro m/m | liwiro m/m | liwiro m/m | liwiro m/m |

| Chitsulo cha carbon | 1 | 8--13 | 15-24 | 24-30 | 30--42 | 40-55 | 60-80 | 70-90 |

| 2 | 3.0--4.5 | 5-7.5 | 5.5-8 | 7--9 | 8--10 | 9--12 | 10--13 | |

| 3 | 1.8--3.0 | 2.4-4 | 3.5-4.8 | 4--6.5 | 4.5-6.5 | 4--7 | 4--7 | |

| 4 | 1.3-1.5 | 2--2.4 | 2.8-3.5 | 3.5-4.5 | 4.0--5.0 | 4.2-5.5 | 4.7-5.5 | |

| 5 | 0.9-1.1 | 1.8-2 | 2.5--3 | 3--3.5 | 3.0--4.2 | 3.5-4.2 | 3.8-4.5 | |

| 6 | 0.6--0.9 | 1.4-1.6 | 1.8--2.6 | 2.5-3.2 | 3.0--3.5 | 3.0--4 | 3.3-4.2 | |

| 8 |

| 0.8--1.2 | 1.2-1.8 | 1.8--2.6 | 2.0--3.0 | 2.2--3.2 | 2.5-3.5 | |

| 10 |

| 0.6--1.0 | 1.1-1.3 | 1.4--2.0 | 1.5-2.5 | 1.8--2.5 | 2.2-2.7 | |

| 12 |

| 0.5-0.8 | 0.9-1.2 | 1.2-1.6 | 1.4--2 | 1.6-2 | 1.8--2.1 | |

| 14 |

|

| 0.7-0.8 | 0.9-1.4 | 1.0--1.6 | 1.5-1.8 | 1.7-1.9 | |

| 16 |

|

| 0.6-0.7 | 0.8--1.2 | 0.8--1.2 | 0.8--1.5 | 0.9-1.7 | |

| 18 |

|

| 0.4--0.6 | 0.7-1 | 0.8--1.1 | 0.9-1.2 | 0.9-1.2 | |

| 20 |

|

|

| 0.6--0.8 | 0.7-1 | 0.8--1.1 | 1.0--1.5 | |

| 22 |

|

|

| 0.4--0.6 | 0.6--0.8 | 0.7-0.9 | 0.8--1.0 | |

| 25 |

|

|

|

| 0.3--0.5 | 0.4--0.6 | 0.5-0.7 | |

| Chitsulo chosapanga dzimbiri | 1 | 8--13 | 18--25 | 24-30 | 30--42 | 40-55 | 60-80 | 70-90 |

| 2 | 2.4--5.0 | 7--12 | 10--17 | 18--21 | 20--30 | 30--42 | 40-55 | |

| 3 | 0.6--0.8 | 1.8--2.5 | 4--6.5 | 8--12 | 12--18 | 18--24 | 30--38 | |

| 4 |

| 1.2--1.3 | 3--4.5 | 6--9 | 8--12 | 10--18 | 18--24 | |

| 5 |

| 0.6--0.7 | 1.8-2.5 | 3.0--5.0 | 4--6.5 | 8--12 | 12--17 | |

| 6 |

|

| 1.2-2.0 | 3.0--4.3 | 4.0--6.5 | 6--9 | 8--14 | |

| 8 |

|

| 0.7-1 | 1.5--2.0 | 1.8--3.0 | 4--5 | 6--8 | |

| 10 |

|

|

| 0.8--1 | 0.8--1.5 | 1.8--2.5 | 3--5 | |

| 12 |

|

|

| 0.5-0.8 | 0.6--1.0 | 1.2-1.8 | 1.8--3 | |

| 15 |

|

|

|

| 0.5-0.8 | 0.6--0.8 | 1.2-1.8 | |

| 20 |

|

|

|

| 0.4--0.5 | 0.5-0.8 | 0.6--0.7 | |

| 25 |

|

|

|

|

| 0.4--0.5 | 0.5-0.6 | |

| 30 |

|

|

|

|

|

| 0.4--0.5 | |

| Aluminiyamu | 1 | 4--5.5 | 6--10 | 20--25 | 25-40 | 40-55 | 55-65 | 80-90 |

| 2 | 0.7-1.5 | 2.8-3.6 | 7--10 | 10--18 | 15--25 | 25-35 | 35-50 | |

| 3 |

| 0.7-1.5 | 4--6 | 7--10 | 10--15 | 13--18 | 21-30 | |

| 4 |

|

| 2--3 | 4--5.5 | 8--10 | 10--12 | 13--18 | |

| 5 |

|

| 1.2-1.8 | 3--4 | 5--7 | 6--10 | 9--12 | |

| 6 |

|

| 0.7-1 | 1.5-2.5 | 3.5-4 | 4--6 | 4.5-8 | |

| 8 |

|

|

| 0.7-1 | 1.5--2 | 2--3 | 4--6 | |

| 10 |

|

|

| 0.5-0.7 | 1--1.5 | 1.5-2.1 | 2.2--3 | |

| 12 |

|

|

|

| 0.7-0.9 | 0.8--1.4 | 1.5--2 | |

| 15 |

|

|

|

| 0.5-0.7 | 0.7-1 | 1--1.6 | |

| 20 |

|

|

|

|

| 0.5-0.7 | 0.7-1 | |

| 25 |

|

|

|

|

|

| 0.5-0.7 | |

| Mkuwa | 1 | 4--5.5 | 6--10 | 14--16 | 25-35 | 35-45 | 50-60 | 70-85 |

| 2 | 0.5--1.0 | 2.8-3.6 | 4.5-6.5 | 10--15 | 10--15 | 25-30 | 30-40 | |

| 3 |

| 0.5--1.0 | 2.5-3.5 | 5--8 | 7--10 | 12--18 | 15-24 | |

| 4 |

|

| 1.5--2 | 3.5-5.0 | 5--8 | 8--10 | 9--15 | |

| 5 |

|

| 1.4-1.6 | 2.5-3.2 | 3.5-5.0 | 6--7 | 7--9 | |

| 6 |

|

|

| 1.2--2.0 | 1.5-2.5 | 3.5-4.5 | 4.5-6.5 | |

| 8 |

|

|

| 0.7-0.9 | 0.8--1.5 | 1.6--2.2 | 2.4-4 | |

| 10 |

|

|

|

| 0.5-0.8 | 0.8--1.4 | 1.5-2.2 | |

| 12 |

|

|

|

|

| 0.6--0.8 | 0.8--1.5 | |

| 16 |

|

|

|

|

|

| 0.6--0.8 | |

Zigawo Zazikulu

Kugwiritsa ntchito

Makampani ogwiritsira ntchito:

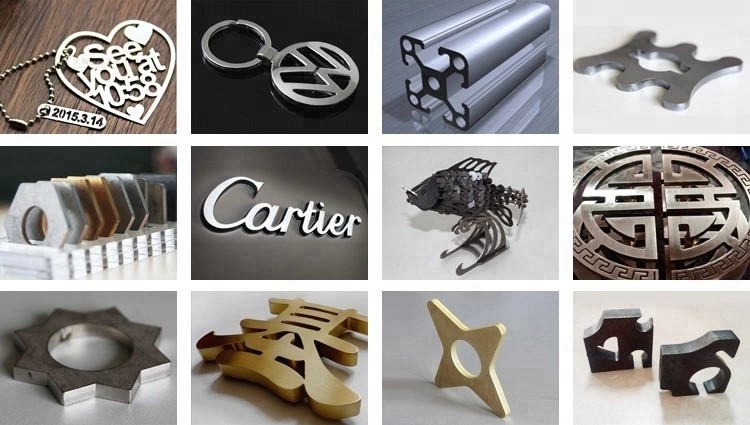

1390 High Precision Laser Cutting Machine imagwiritsidwa ntchito kwambiri popanga Billboard, Kutsatsa, Zizindikiro, Zikwangwani, Zitsulo, Letters LED, Kitchen Ware, Letters Advertising, Sheet Metal Processing, Zitsulo Zigawo ndi Zigawo, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Crafts, Hardware Art Ware, Hardware Art Ware. Frame, Electronic Parts, Nameplates, etc.onetsetsani kuti itha kugwira ntchito ng zotheka panthawi yodula laser.

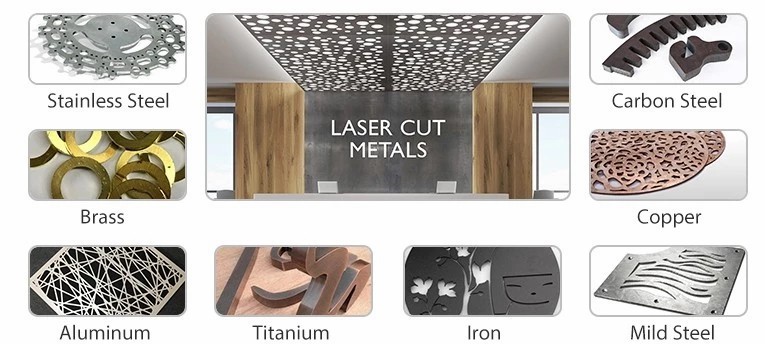

Zipangizo Zofunsira:

Stainless Steel Sheet, Mild Steel Sheet, Carbon Steel Sheet, Alloy Steel Sheet, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminium Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Plate Sheet, Metal Sheet, Tube, etc.

Zitsanzo

Ubwino

1.Kudula bwino, mpaka 0.05-0.1mm. Gwiritsani ntchito mpweya wothandiza woyenerera, kupangitsa kuti ming'alu ikhale yabwino komanso yosalala, osafunikira kupukuta kwachiwiri.

2.Kuyang'ana mutu wodula zokha.kugwiritsira ntchito kunja kwapamwamba-kupita patsogolo capacitive sensa, nthawi zonse zomveka zolondolera mbale kutalika.Kusintha kutalika kwa kudula kokha kumalepheretsa kugunda, mukhoza kudula mbale yosagwirizana.

3. Makina odulira amatengera servo motor drive yochokera kunja, kutengera moduli yolondola kwambiri, yofulumira, yolondola kwambiri mpaka 0.01mm. Moyo wautali wautumiki.

4.Kugwiritsa ntchito ma lasers apamwamba kwambiri, zida zazikuluzikulu zimatumizidwa kunja. Kukhazikika kwakukulu, moyo wautali, wopanda zoperekera, zosamalira.

5.Professional design ya golide ufa kuchira chipangizo, fumbi ndi fumbi anasonkhanitsa onse kuchira chipangizo. Kotero kuti imfa ndi osachepera.

6.For golide ndi siliva zodzikongoletsera makampani akatswiri mwambo laser kudula dongosolo, ndi kukhathamiritsa njira, kudula poyambira kukhathamiritsa, Mipikisano wosanjikiza, masanjidwe ntchito, kusunga nthawi ndi chuma.

7.Kukula kwakung'ono, kugwiritsa ntchito mphamvu zochepa, kuchepa kwapang'onopang'ono, kukonza kosavuta. Ndi wothinikizidwa mpweya angathenso kudula, mtengo wotsika.